User:Leebc

Jump to navigation

Jump to search

About me

What I Make

Classes I Teach

- None.

Classes I could be talked into teaching if there is enough explicit interest:

- "Designing laser-cuttable model buildings for D&D, railroad, and other miniatures terrain"

- "Introduction to pottery: Pinch pots, coil pots, and slab pots" (This may be 2 or 3 separate classes.

- "Designing 3d printable furniture in OpenSCAD"

- "A method for creating UV maps/textures for 3d models for use in Unity3d"

Interests

- MAPS!

- Laser cutting flat things and turning into 3d things

- Visualizing strange data

Slack Channels I post in

Some of my projects

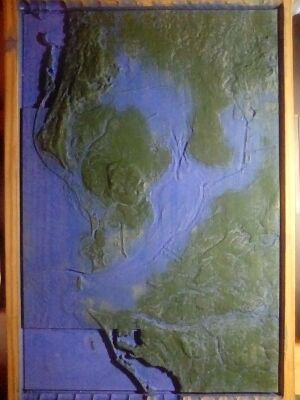

Maps!

Laser cut DOMES!

Research

Lasercut Frames

Some collected thoughts on laser-cutting picture frame

Asked in slack and on facebook:

- Does anyone have any thoughts on finishing laser-cut picture frames?

- I could cut multiple parts out of 1/8th" or 1/16th" material and glue together, but my real concern and question is about finishing the edges.

- MDF or acrylic would have a clean edge, and the whole thing could be painted... but what if you were using 1/8" or 1/4" plywood?

- Can you think of a material that would be better for picture frames?

- How hard is it to work with a stick-on veneer?

- What kind of paint?

Some suggestions include:

- vinyl wrap the frame

- "Cheaper material like Plywood could get cleaned up with some of the same techniques and materials as 3d printed parts, Water putty/spot putty to fill in voids and then sand able primer and you can get a very clean surface to paint to get the same finish as solid wood parts."

- Another suggestion is to laser-cut a bevel using a jig. This should work if the frame pieces are thin enough and narrow enough.

- Acrylic mirror could be really nice.

- I love stick on veneer. I laser cut it and use it with finished plywood in layers. I just make sure to laser myself a template on the bottom layer because it’s really hard to line stuff up without it. I also like the look of veneer on top of acrylic too.

- Otherwise I feel like a [beveled] edge is really a nice finish for frames if you have the tools. So I would probably do that then paint/stain, spray with the triple thick clear topcoat (sand in between coats) if I want the grain or maybe top it with a thin layer of resin if not. I’m kinda addicted to how easy and quick UV resin is but regular resin would be so quick if you had several to do.

- It's not really a frame. The trapezoid shapes are glued to the back. The QR code is vinyl cut. The border is cheap 5mm lauan stained. Finished with polycrylic. Could probably glue/epoxy/adhere a border on clear acrylic.

Acrylic mirror:

- Could make a mirror by cutting a back plate of mirrored acrylic, then acrylic cement or CA glue on some black or white strips of acrylic like this <image>. Maybe put some round or shaped holes in them so the mirror...uh... mirrors through.

- Or could paint the black & white on using masking as a template or use a thin veneer so the mirror isn’t too shadowed

- Acrylic frame with mirrored edges (black background) <other image>